Our history

We keep the world moving

– since 1864.

The world’s first engine factory was established that year under the name of N. A. Otto & Cie. DEUTZ boasts a history of many highlights: from the invention of the Otto engine to DEUTZ’s first hydrogen engine, the TCG 7.8 H2.

Milestones

DEUTZ celebrates its 160th anniversary with a ceremony

DEUTZ AG celebrates its 160th anniversary on 3 May 2024 with a ceremony in Cologne. Guests from politics, business and society have gathered at the former site of the world's oldest engine manufacturer. The Minister President of North Rhine-Westphalia, Hendrik Wüst, and the Lord Mayor of Cologne, Henriette Reker, also have paid tribute to the company. DEUTZ also presented this year's Nicolaus August Otto Award.

DEUTZ acquires Blue Star Power Systems

By making this move, DEUTZ is advancing its growth in the rapidly developing sector of decentralized energy supply and is establishing a foundation to provide complete solutions for local power generation. This marks a significant shift for DEUTZ from being a component manufacturer to becoming a solutions provider.

DEUTZ NewTech segment with its own CEO

The company has announced at the Annual General Meeting that Bert van Hasselt will be the new CEO responsible for the DEUTZ NewTech segment and the focused development of alternative powertrains. The decision follows the reorganisation of the segment initiated last year.

DEUTZ opens HVO refuelling station on the Cologne site

Since June 2024, all the Group's diesel-powered vehicles at the site have been able to use the paraffinic diesel fuel HVO. This applies to the company's entire fleet in Cologne, including company cars, Deutz safety vehicles, forklifts and test and service vehicles.

DEUTZ sells Torqeedo to strategic investor Yamaha Motor Co., Ltd.

DEUTZ is selling Torqeedo, the world's leading manufacturer of outboard and inboard engines, to Yamaha Motor Co, Ltd. The sale of Torqeedo frees up resources for DEUTZ to focus on the development of alternative propulsion solutions in the future and to focus more strongly on market and customer needs.

DEUTZ expands service business

The Diesel Motor Nordic Group (DMN), with operations in Sweden, Denmark and Finland, has been fully acquired by DEUTZ AG. The group will now operate under the name DEUTZ Nordic. The global expansion of the service and parts business is one of the three key elements of the "Dual+" strategy: DEUTZ intends to improve the performance of its existing business with conventional engines and significantly expand its existing service business in order to further develop its future-proof technology portfolio.

Cooperation with Daimler Truck

DEUTZ develops and markets engines in cooperation with Daimler Truck – an important step towards further growth in its business with modern internal combustion engines. The cooperation was agreed in January and is underpinned by Daimler Truck's acquisition of a 4.19 percent stake in DEUTZ. The deal gives DEUTZ access to technologically advanced engines, will attract new customer groups, and will save development costs.

New management board team focussing on future challenges

DEUTZ is reorganising its Board of Management. Dr Sebastian C. Schulte, previously Chief Financial Officer and Labour Director, will take over as Chairman of the Management Board of DEUTZ AG in February. In addition to the appointment of Dr Petra Mayer as Chief Operating Officer (COO) from November, DEUTZ AG is also appointing Timo Krutoff as the new Chief Financial Officer (CFO) and Labour Director. Dr Markus Müller, Chief Technology Officer (CTO) of DEUTZ AG, will also assume responsibility for sales. Unlike previously, the CEOs of the regions will from now on report directly to DEUTZ CEO Dr Sebastian C. Schulte.

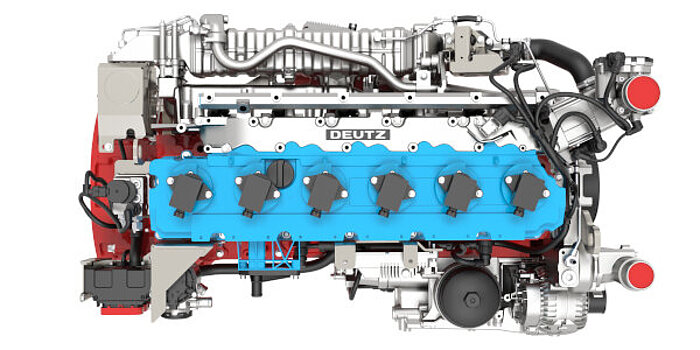

DEUTZ hydrogen engine proves suitable in pilot project

In partnership with RheinEnergie AG, DEUTZ will begin testing stationary power generation based on its TCG 7.8 H2 hydrogen engine in the summer of 2022. As part of this flagship project, the first H2 genset will be put into operation at the RheinEnergie combined heat and power plant in Cologne. The engine is proving to be suitable for decentralised urban energy supply. Combined with heat storage, heat pumps, solar installations and electricity storage, the technology makes it possible to supply entire neighbourhoods on a climate-neutral basis.

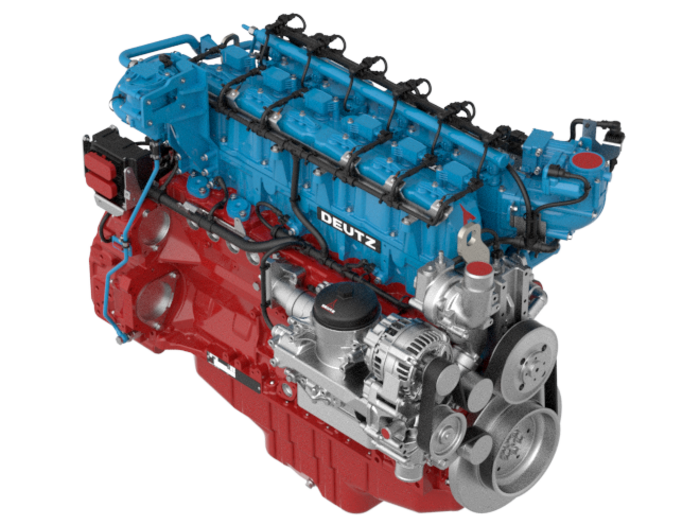

New green segment

From 1 January 2022, all activities related to the development and production of new powertrains beyond the diesel engine will be included in the 'Green' segment. This includes electric technologies such as the E360 drive system, high-voltage battery systems, the PowerTree and the hydrogen engine. The new segment reporting also makes DEUTZ's hydrogen engines and fuel cell activities much more visible.

DEUTZ further expands global service network

In 2022 DEUTZ acquires its former service partners AUSMA Motorenrevisie B.V. (Netherlands) and South Coast Diesels (Ireland). These companies sell and service diesel engines in their home markets. In addition, the new sales and service company in Stockstadt am Rhein brings DEUTZ even closer to its German customers.

DEUTZ builds its ten millionth engine

On 11 November, DEUTZ will celebrate its ten millionth engine, a TCG 7.8 H2 hydrogen engine, which, like the original, is a four-stroke engine. "With the development and production of low-emission hybrid, fuel cell and e-fuel engines, DEUTZ is continuing in the tradition of its founder, Nicolaus August Otto," said Ina Brandes, Minister of Transport of the State of North Rhine-Westphalia, at the ceremony in the DEUTZ assembly hall.

DEUTZ unveils its first market-ready hydrogen engine

In August, the drive systems specialist presents its first marketable hydrogen engine, the DEUTZ TCG 7.8 H2. The company is once again expanding its range of low- and zero-emission engines. The hydrogen engine is climate-neutral, very quiet and produces 200 kW of power. It is suitable for all applications.

Joining forces: DEUTZ and John Deere Power Systems

DEUTZ unlocks further growth potential by joining forces with other industry leaders. In December 2020, DEUTZ and John Deere Power System agreed to work together. They will build a new engine in the power range up to 130kW. The two companies will work together on the development and sourcing of components, and then produce and sell the engines separately.

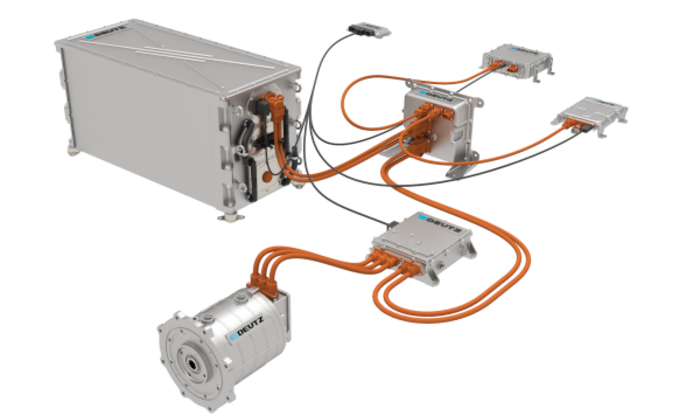

Pioneering environmentally friendly, efficient drive systems

By the end of 2020, DEUTZ will have laid the foundations for the industrialisation of electric and hybrid drive systems. The 360-volt basic drive system is the first fully electric DEUTZ engine. This electric engine has a power output of up to 75 kW and will be used primarily in ground support equipment, construction and agriculture.

Taking Responsibility – the first group-wide sustainability strategy

DEUTZ has adopted a Group-wide sustainability strategy. Our aim to be commercially successful while fulfilling our corporate, social and environmental responsibilities is reflected in our guiding principle 'Taking Responsibility'.

This framework sets targets for 2023, such as reducing emissions from our plants and increasing employee engagement. The full set of objectives is contained in the "DEUTZ Sustainability Vision 2023".

DEUTZ acquires battery specialist Futavis

DEUTZ acquires Futavis, a developer of battery management hardware and software. With this acquisition, DEUTZ adds batteries as a key component to its electrification strategy. Futavis has extensive technical expertise in electronics, software, battery technology, battery testing and ensuring functional safety. The acquisition adds high-voltage battery technology to DEUTZ's systems expertise in the field of electric drives, which is provided by its subsidiary Torqeedo.

DEUTZ Advanced Configurator: a modular system for customized drive solutions

Its product portfolio enables DEUTZ to respond quickly and flexibly to technological developments and changing market conditions. With the modular Advanced Configurator, DEUTZ offers the best combination of conventional and electric drives. The customised solutions reduce carbon emissions, fuel consumption and overall costs. Good news for the planet. Good news for our customers.

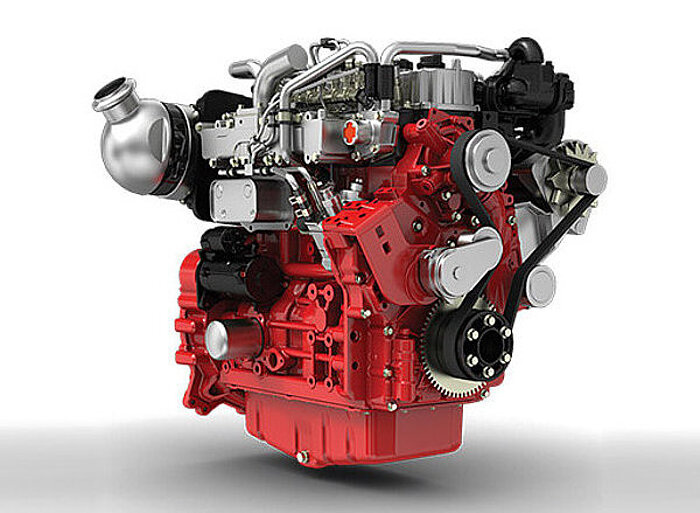

Pole position: DEUTZ engines are Stage V ready

DEUTZ is making its engines cleaner. With the "Stage V ready" seal, DEUTZ is the first engine manufacturer to promise its customers engines that comply with the EU's Stage V emissions directive, which will come into force in 2019. The DEUTZ TCD Stage IV engine generation already has the necessary exhaust aftertreatment systems, including diesel particulate filters. Since the design and construction of the engines will remain identical, there will be no major costs on the way to lower emissions.

DEUTZ presents the TCD 2.9 and TCD 3.6 compact engines

A completely new generation of engines for the construction industry makes its debut. At Bauma 2010, DEUTZ is presenting the ultra-compact four-cylinder engine series, which has been specially developed to meet the needs of the industry in the lower power range. Thanks to a customer-oriented system of add-on components, the engines offer flexible installation options and significantly lower installation and operating costs. With the introduction of exhaust emission standard IV, the new TCD 2.9 and TCD 3.6 build on the legendary DEUTZ 2011 series, which is still in production for the previous emission standard.

Taking up global challenges

In mid-2003 DEUTZ AG signed a cooperation agreement with the SAME DEUTZ-FAHR Group, an Italian manufacturer of agricultural machinery. The Italian group becomes DEUTZ AG's largest shareholder. With this agreement, the Cologne-based company, which already has a strong partner in Volvo, once again becomes the main supplier of diesel engines - this time for tractors and harvesting machinery. SAME and DEUTZ have had a close relationship since 1995. In that year, SAME took over the agricultural machinery division of DEUTZ-FAHR from the former Klöckner-Humboldt-DEUTZ AG. SAME is based in Treviglio near Milan. It is one of the world's largest tractor manufacturers and has since become one of the most important buyers of agricultural engines from Cologne.

For the SAME Group the investment in DEUTZ is a strategic decision. Future European limits on exhaust and noise emissions mean high investment in engine development. Against this background, the number of engines built by SAME itself is too small for profitable production. The new cooperation solves this problem in the long term: In the medium term, SAME DEUTZ-FAHR will probably cease producing its own engines altogether. For DEUTZ, this means an additional annual volume of around 25,000 agricultural engines. This will further consolidate the company's independence as an engine specialist and prepare DEUTZ for future challenges - agricultural machinery is a key global growth market.

DEUTZ cooperates with Volvo

DEUTZ AG focuses on cooperation: In October 1998 the company signs a cooperation agreement with the Swedish vehicle and engineering group Volvo. Over the next few years DEUTZ becomes the main supplier of engines in the important 4 to 7-litre range for the Swedish machines. The two partners are also working together on new developments in this class. To underline the long-term nature of this partnership, Volvo is taking a ten percent stake in the subscribed capital of DEUTZ AG.

DEUTZ supplies more than 100 prototype engines to Volvo during the intensive planning and project years between 1999 and 2001. Series production begins in 2002: As part of the cooperation, Volvo off-highway products and equipment in the 4 to 7 litre capacity range will be equipped with Volvo engines from DEUTZ. To this day, DEUTZ and Volvo engineers are motivated by Otto's vision and innovation: The partners develop an engine with a specially developed fuel injection system, the DEUTZ Common Rail. The new diesel engine proves itself in a test bench cycle.

State of the art: The new motorworks in Cologne-Porz is put into operation

In June 1993, the new engine plant in Cologne-Porz officially opened. It was one of the most modern of its kind. It was here that the successful 1011 series was assembled. With a volume of around DM 600 million, it was also the largest single investment in the history of the Klöckner-Humboldt-Deutz (KHD) group. The 500,000th unit rolls off the production line in 2020: The oil/air-cooled engine was a bestseller.

The unrivaled all-rounder

A new engine class sets new standards. For the first time, DEUTZ is supplying an engine with an integrated cooling system. The oil not only ensures correct lubrication, but also keeps the running temperature under control. Production of the 1011 series begins in 1988. Twelve years later, the 500,000th unit rolls off the assembly line. It is a masterpiece of engineering: Only a slightly increased amount of oil is needed to lubricate the engine and maintain a safe operating temperature at various loads. This cooling method also significantly reduces the noise level of the engine. The type of cooling and the power range make this series unique on the world market.

Magirus-DEUTZ Saturn II, the bestseller

The sight of the Magirus-DEUTZ Saturn II still warms the hearts of vintage truck fans. Thanks to its air suspension, the chassis could be lowered at the bus stop - a convenience that would only become standard on kneeling buses decades later. From 1958, the only other customer apart from the Cologne transport authority was the Hamburg Hochbahn, which bought 535 city buses and 130 express buses of this type. For a time, DEUTZ was able to increase its market share in Germany to 15 percent. In 1980 the company withdrew from the vehicle sector. As a specialist in small series production, DEUTZ now supplies engines to commercial vehicle manufacturers all over the world.

75 years – and still going strong: the Otto engine

The spark ignition engine, the "ancestor" of almost all internal combustion engines, celebrates its 75th birthday. In the same year, the 50,000th diesel tractor rolled off the production line. At the same time, production of the highly successful F1M414 water-cooled diesel tractor is discontinued. All DEUTZ tractors are now air-cooled. In 1954 DEUTZ builds its 100,000th air-cooled diesel engine. 35 years later, more than four million units have been sold.

Reconstruction after the war

Five years after the end of the war, production was almost back to normal. 60 per cent of the buildings were back in use, and the 13,000 employees were producing 40,000 engines with a total output of around 1.5 million hp. 10,000 tractors and 6,000 commercial vehicles leave the workshops in Cologne and Ulm. The first apprentices complete their training and the first issue of the "Factory Review" is published.

Cool heads rely on air

The air-cooled diesel engine goes into series production. Thanks to its simple design, the engine is a great success - and makes DEUTZ AG the world's largest supplier of this engine technology. It takes DEUTZ no more than two years to develop the engine: In 1944 the first air-cooled diesel engines rolled off the assembly line in Ulm. Originally developed for military purposes, the engine can withstand both frost and extreme heat.

During the war, in the winter of 1944/45, production at both sites was badly damaged. By the end of the war, not much remained of the Cologne plants - 74 percent of the site had been destroyed. Reconstruction began and the Allies authorised DEUTZ to bring back machine tools that had been evacuated during the war. DEUTZ is allowed to manufacture mining equipment and, in 1946, even 500 tractors.

DEUTZ enters commercial vehicle business: acquisition of C.D. Magirus AG

Trucks with four-wheel drive, buses for local and long-distance transport, emergency vehicles. With the takeover of Ulm-based C.D. Magirus AG, DEUTZ makes a grand entrance into the commercial vehicle business. The company's broad product range now includes fire-fighting vehicles, trucks and special all-wheel-drive vehicles for military use. The new Ulm plant also produces buses for local and long-distance transport. The bus quickly became a serious competitor to trains and trolleys, improving urban transport in cities such as Hamburg, Munich and Berlin. Demand was considerable: DEUTZ received orders from the Amazon to the Amur.

42 years later the company received the biggest single order in its history. It supplied 10,000 trucks to the former Soviet Union. From 1974 onwards, this mighty fleet was used primarily in a gigantic construction project in the USSR: the Baikal-Amur Main Line. This 1950-mile railway line links the western Baikal region to the south-eastern border with China.

DEUTZ adds momentum to agricultural engineering

At the beginning of the last century, farmers still often used horses to harvest their crops. In some places, huge steam ploughs may have been in use. But 1 hp is not always enough, and the machines are expensive. In 1926 DEUTZ launched a real alternative: the MTH 222. It was the first DEUTZ diesel tractor to go into series production. It clearly made work easier and agriculture more efficient. DEUTZ is still committed to these goals today. The MTH 222 has a frame construction, a two-speed gearbox, chain drive and evaporative cooling. Its recumbent single-cylinder four-stroke diesel engine produces 14 hp.

This diesel tractor enabled farmland to be used much more efficiently. In 1929, the new MTZ series was launched, including the 30-hp 220 model. Two years after its launch, the design was awarded the silver medal of the German Agricultural Society. Business boomed. By 1936 alone, more than 2,000 units of the MTZ 320 had been sold. Not surprisingly, most of the buyers came from the agricultural sector. Who would ever think that DEUTZ tractors would be powering the cars in the Cologne carnival parade?

VM Series with airless direct fuel injection

In 1921, the VM series (short for "Viertakt-Motor": four-stroke engine) with airless direct fuel injection was launched - and became an overnight sensation. Its main attraction was its extremely low fuel consumption, even at partial load. The specific fuel consumption of 168 grams per horsepower per hour remains exemplary to this day. In addition, the DEUTZ direct injection engine quickly became the benchmark for emission quality. In 1924 the so-called precombustion chamber process for high-speed four-stroke diesel engines goes into series production.

DEUTZ celebrates its 50th anniversary

In 1914 DEUTZ celebrates its 50th anniversary: The publicly owned company employs 3,300 workers and 400 salaried employees and produces engines with a total output of around 90,000 HP.

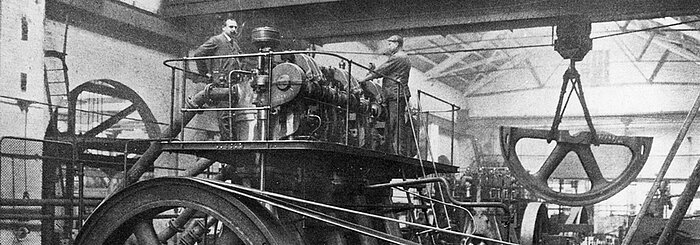

The triumphant progress of automatic ignition

The start of mass production of diesel engines in 1907 opened up new markets and applications for DEUTZ AG. Having developed its own diesel engines over the years, the company was in an excellent position. DEUTZ is able to offer a comprehensive range of self-igniting engines without delay. This has paid off to this day: Around 1.3 million DEUTZ diesel engines are currently in use around the world.

On the basis of a licence agreement with Maschinenfabrik Augsburg (now MAN) and Krupp, the DEUTZ gas engine factory has been manufacturing diesel engines since 1897. From 1898, however, the factory began to develop its own diesel engines. Three years later, DEUTZ terminated the licence agreement in order to concentrate more on its own diesel engine production. This approach soon paid off. On 28 February 1907, the patent for the diesel process held by Rudolf Diesel and the MAN predecessor company expired. DEUTZ seized the opportunity with its existing knowledge and, with a workforce of around 3,500, began mass production of diesel engines on 1 March 1907. Right from the start, the engineers offered a comprehensive range of engines.

The largest self-ignition engines to come out of the forges in the Deutz district of Cologne produce an impressive 400 hp. Energy and transport - generators, pumps and marine propulsion - are the main areas of application for the engines. In 1911 DEUTZ launched the first compressorless diesel engine in series production.

Four-stroke goes mobile with fluid fuels

Otto is haunted by his engines' dependence on the public gas network. The machines are stationary. Like street lamps, they need a pilot light. It was impossible to use them in mobile applications such as vehicles. This changed in 1884 when Otto introduced his low-voltage magneto ignition. Electric ignition made it possible for engines to run on liquid fuels for the first time. Otto's development was taken over by Robert Bosch and became the basis of his life's work. Nicolaus August Otto dies in 1891. The inventor of the four-stroke internal combustion engine was only 59 years old.

However, this sad event did not stop technical progress. In 1892, DEUTZ began manufacturing locomotives with internal combustion engines. The first prototype is delivered to the Radebeul chemical works. In 1896 the world's first mining locomotive is built. Just two years later, DEUTZ presents the first diesel engine of its own design. Eugen Langen, the company's co-founder, did not live to see this. He died in October 1895.

Gasmotoren-Fabrik DEUTZ AG starts mass production of the four-stroke engine

In 1877, Nicolaus August Otto protected the four-stroke process with the world-renowned DRP 532 patent. In the same year, mass production of the four-stroke engine began at Gasmotoren-Fabrik Deutz AG, founded in 1872. The company's technical director was Gottlieb Daimler, and the head of engine design was Wilhelm Maybach. The four-stroke engine was launched as "Otto's new engine" - a slogan that sold. At the same time, the international business picked up speed. The new DEUTZ engines are now also built - and sold - in England and the USA, either under licence or directly by subsidiaries.

Four strokes that move the world

When Nicolaus August Otto invented the four-stroke engine in 1876, he changed the world. Almost all internal combustion engines, regardless of the fuel they use, operate according to Otto's principle. Our modern way of life would be unthinkable without these four strokes: They provide power in operating theatres, ensure reliable data transmission around the world, enable grain to be harvested quickly and efficiently, and make robust long-distance coaches and powerful tugboats possible in ports.

The working diagram of an experimental engine is the "birth certificate" of the Otto engine. On 9 May 1876 in Cologne, Nicolaus August Otto completed his four-stroke engine with compressed charge, suitable for all types of fuel and applications. The machine, still powered by coal gas, produced 3 hp at 180 rpm - and set us on the road to a motorised world.

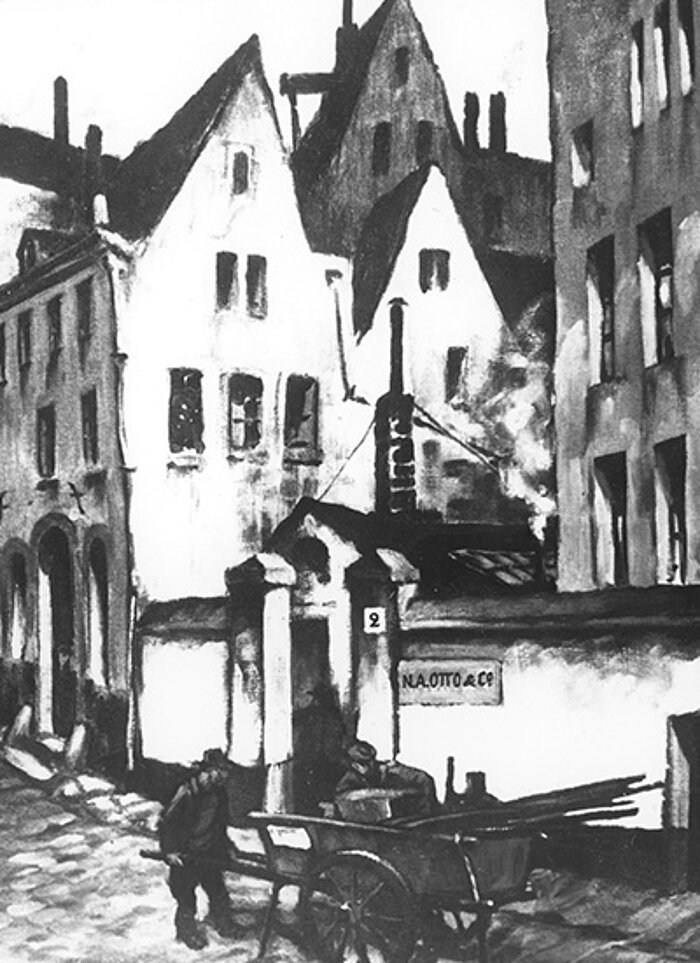

The origin of DEUTZ AG

The vision and tireless experimentation of Nicolaus August Otto revolutionised the world. His development of the four-stroke engine laid the foundations for global motorisation - and today's mobile society. In 1864, together with engineer Eugen Langen, the inventor founded N.A. Otto & Cie. Their small workshop in the old town of Cologne is the world's first engine forge and the origin of today's DEUTZ AG.

As a businessman and travelling salesman, Nicolaus August Otto was almost always on the road. It was an inconvenient and time-consuming business. With his keen interest in technology, Otto decided to change this. In 1860 he heard about the coal-gas engine, an invention of the Frenchman Etienne Lenoir. This made Otto curious. The idea was born to build a machine that could be "easily and practically used for the locomotive of vehicles on country roads, as well as being of considerable benefit to light industry". This is what Otto wrote in 1861 in his first patent application to the Royal Prussian Ministry of Trade. The patent for a spirit carburettor, which promised to make the engine independent of the public gas network, was rejected. Nevertheless, Otto concentrated his efforts on the world of engines.

The Cologne mechanic Michael Zons built him a model of Lenoir's engine. Otto conducted his own experiments to discover the effects of a compressed gas-air mixture. He immediately began experimenting with a four-stroke engine of his own design. The principle of four-stroke induction, compression, combustion and exhaust was as brilliant as it was revolutionary. However, the engineer was unable to control the violent ignition of the four cylinders. As a result, after a short period of use, the engine was reduced to fragments. In 1863 Otto built and tested his first "atmospheric gas engine". He believed he was on the right track. But money was running out and the inventor was at the end of his tether. But one man was interested in the gas-powered machine, and he was eventually persuaded: Eugen Langen, an engineer in the Cologne sugar trade, invested in Otto's ideas and skills.

On 31 March 1864, Otto and Langen founded the company N.A. Otto & Cie. The former provided the know-how, the latter the money and, above all, the entrepreneurial skills. They set up the "world's first engine factory" - the origin of today's DEUTZ AG. In their workshop in Cologne's Servasgasse, the story of a unique company begins.

Striking Heads

DEUTZ’s corporate history – associated with many great names

Our people are the engine of our company’s success. This goes for our entire team, and the many personalities whose names stand for drive systems, technology, and progress to this day: striking heads of engine history.