Fuels of the Future

Hydrogen -

A clean source

of energy

Hydrogen is a naturally occurring chemical element. It is a key building block for a climate-friendly energy supply of the future.

Technology of tomorrow having an impact today

Faced with global climate crisis, countries around the world are taking far-reaching measures to meet their climate targets and limit global warming to 1.5 degrees Celsius as set out in the Paris Agreement. The development of alternative power systems play a central role, with hydrogen as a clean energy source receiving particular attention.

Hydrogen holds huge promise as a future energy source. And even today, it has the potential to reduce environmental impacts when used as a fuel. This is why DEUTZ has been intensively involved in the pioneering technology of hydrogen combustion engines for many years now. So intensively that we already have on in commercial production.

FAQ

Hydrogen is a naturally occurring chemical element and a key component of future climate-friendly energy supply. Hydrogen usually exists as a molecule and can be stored, transported and used as an energy carrier in gaseous or liquid form for energy conversion (reconversion into electricity). Hydrogen is usually found in nature in the form of compounds and must therefore be separated from a hydrogen-rich starting material using energy. These may include

- Natural gas

- Other hydrocarbons such as oil

- Biomass

- Water

- Other compounds containing hydrogen (e.g. ammonia NH3)

Chemical, electrical, thermal or solar energy can be used to separate these substances and produce pure, uncombined hydrogen. Depending on the production process, the hydrogen produced is colloquially described by different colours.

Hydrogen is a very flammable gas. However, it is assigned different colours depending on its origin.

Green hydrogen is produced by electrolysis of water. This is done using electricity from renewable energy sources that do not release CO2 into the atmosphere. No CO2 is released during the production of green hydrogen.

Grey hydrogen is usually produced from fossil natural gas by steam reforming. This produces about 10 tonnes of CO2 per tonne of hydrogen. The CO2 is released into the atmosphere. This hydrogen needs to be replaced with climate-friendly hydrogen.

Blue hydrogen is grey hydrogen produced by storing the CO2 instead of releasing it into the atmosphere (CCS, Carbon Capture and Storage). This process can store up to 90% of the CO2.

Orange hydrogen is hydrogen produced from waste and residual materials. It is considered CO2 neutral.

Turquoise hydrogen is hydrogen produced by thermal decomposition of methane (methane pyrolysis). Instead of CO2, it produces solid carbon that does not escape into the atmosphere. The methane pyrolysis process is still under development.

White hydrogen is found in natural deposits. Whether it can be used in the future is still unclear. The formation of white hydrogen and its transport in the Earth's crust are still poorly understood.

In its pure form, hydrogen can be stored as a compressed gas in pressurised containers or as a cryogenic liquid in insulated containers. It can also be chemically bonded and stored in the form of synthetic fuels or LOHC (Liquid Organic Hydrogen Carrier). In this way, the bound hydrogen can also be stored under normal conditions in conventional tanks for crude oil and petroleum products.

Existing underground pore or salt cavern storage facilities can also be considered as stationary hydrogen storage for gaseous and chemically bound hydrogen. These are currently used to store natural gas and crude oil.

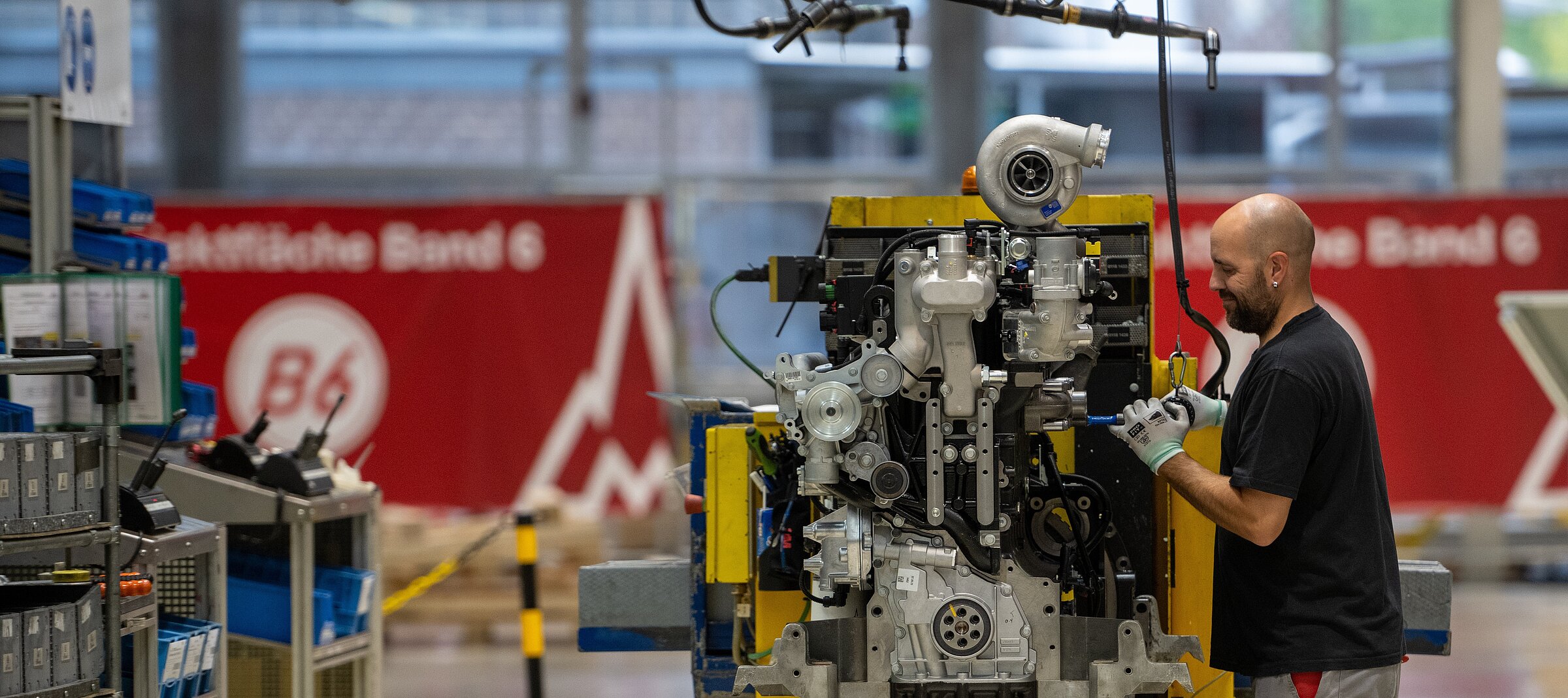

The hydrogen engine is essentially a gas engine. This means it is based on the same principles as a conventional combustion engine. In other words, on the classic Otto, or four-strole, cycle. The difference is that hydrogen is burned instead of gasoline or diesel - and it produces water.

A pressure control valve on the engine brings the hydrogen arriving from the storage tank to a stable operating pressure and regulaes the amount of fuel flowing in. The gaseous hydrogen, together with the intake air, is drawn into the piston chamber via a charge air line. The piston compresses the mixture in this chamber, increasing the temperature and pressure. The spark plug then ignites the compressed hydrogen-air mixture, which causes the gases to expand rapidly and push the piston downward. This movement converts the chemical energy into mechanical work and drives the engine. The piston then rises again and forces the combustion gases - in this case mainly water vapor - out of the cylinder and into the exhaust manifold.

Despite the differences between hydrogen and conventional fuels such as gasoling, gas (e.g. LPF, CNG), and diesel, key components such as the cylinder crankcase, cylinder head, and oil sump are largely the same. Only add-on parts - for example, the fuel routing and the fresh air and exhaust pipeline, including turbocharging, and the sensors and software - need to be modified to ensure optimum combustion of the hydrogen. Theses lines can be made slightly larger thanks to the higher air flow rate dring lean-bum operation. Howerver the size and weight of the engine remain virtually unchanged.