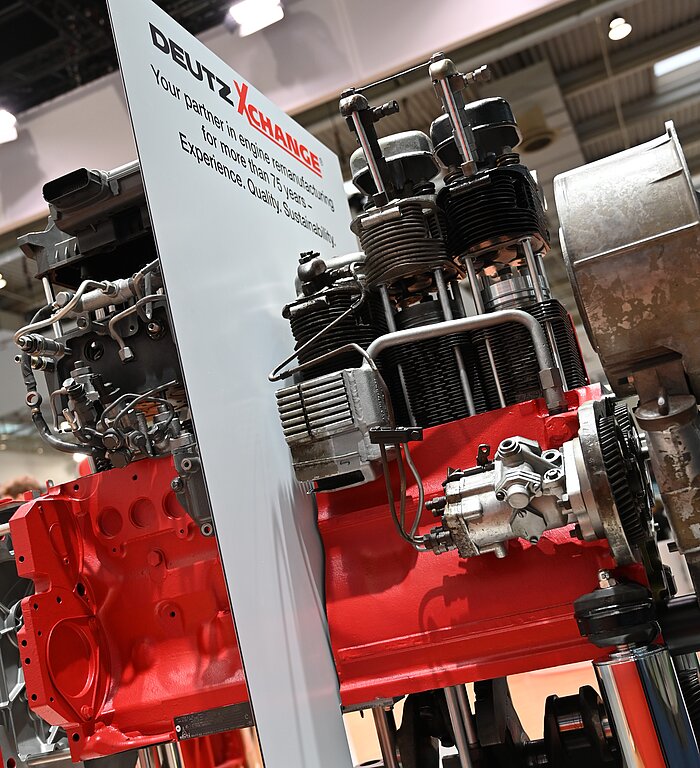

In Ulm, a team of third-year apprentices developed an extraordinary tradeshow engine in a short period of time. The aim was to show what is possible with DEUTZ Xchange through remanufacturing. Whether it’s state-of-the-art diesel technology or proven classic engine technology – reconditioning (almost) always works at DEUTZ. For this purpose, two very different DEUTZ engines – an air-cooled 912 from 1970 and a modern water-cooled TTCD 6.1 engine – were presented in such a way that the technical differences and the condition “old vs. remanufactured” are clearly visible.

The project is directly linked to DEUTZ Xchange, our program for professional engine remanufacturing as a sustainable and cost-efficient alternative to buying new. The exhibit makes the idea behind Xchange tangible and shows how remanufactured engines can be brought back into top form – regardless of whether they have been in use for just a few years or for decades.

To implement the concept, both engines were first cut in half, some of the components were then refitted, and subsequently presented as a “merged” view. This created an illustrative comparison between engines after their first life and engines with a second life thanks to DEUTZ Xchange.

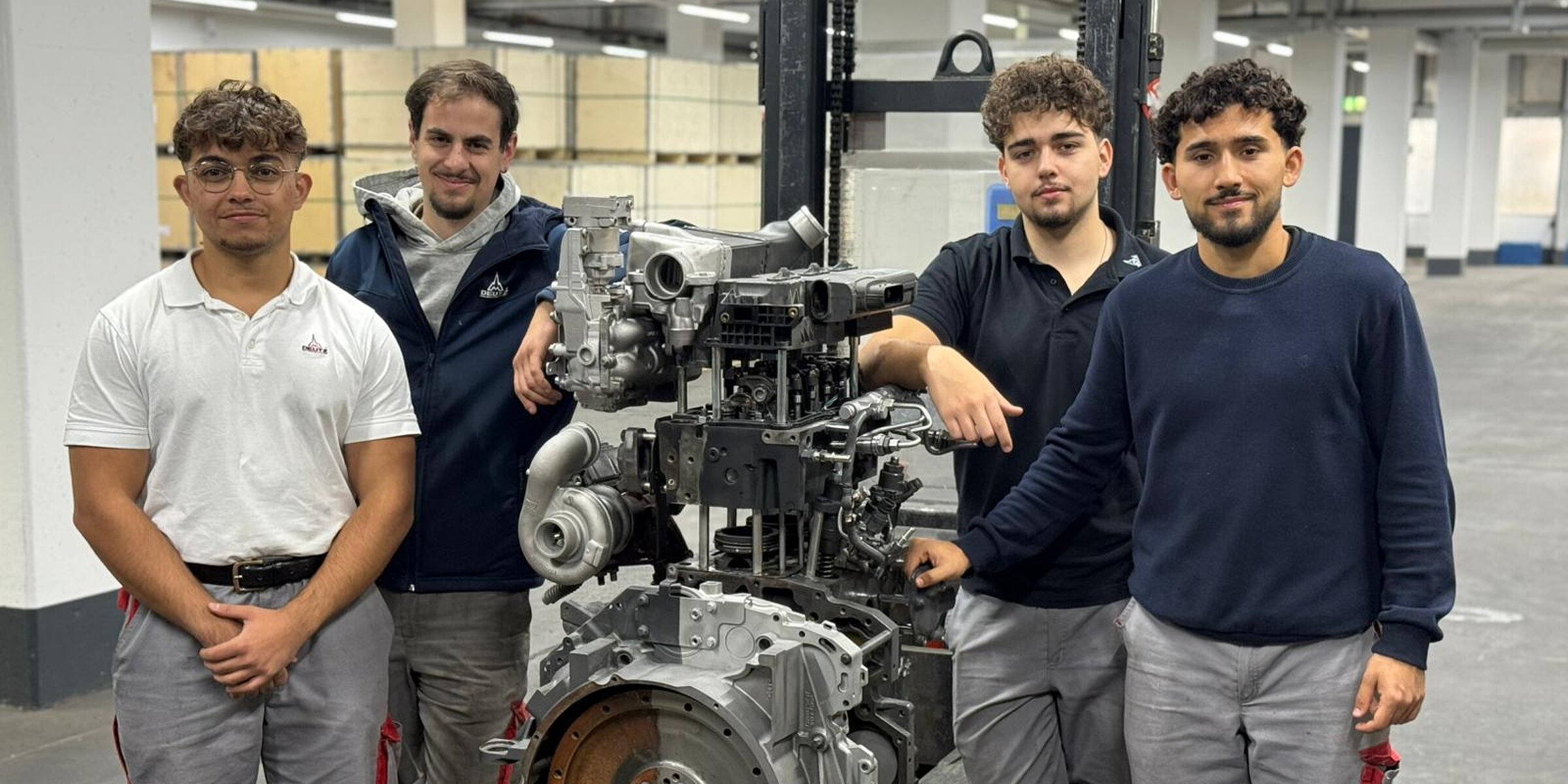

The projectstarted at theendofJuly 2025 and was alreadycompletedbyearlyOctober. The apprentices carried out all workstepsindependently – withgreatcommitment, creativity, and theuseofthesimplestresources.

At its first presentation at AGRITECHNICA in Hanover, November 2025, the finished engine exhibit attracted great interest and once again demonstrated how practice-oriented and high-performing our training is.

First presentation of the finished engine exhibit at AGRITECHNICA in Hanover, November 2025.